Valentines day is just a few weeks away, so I figure now is the time to post a tutorial for making a simple wire heart pendant! This is a basic heart, but once you create it, you can embellish it however you want…

You will need basic wire jewelry pliers (chain or bent-nose, round nose, cutters), a small file, a hammer and steel block. You will also need 16g wire and 24g or 26g wire, and a mandrel about 1/2 inch diameter… a fat marker works well.

To start…. cut a piece of 16g wire 5 inches long, and file the ends so that they are flush. Then bend the wire using your chain nose pliers, so that one side is 2.25 inches, and the other is 2.75 inches.

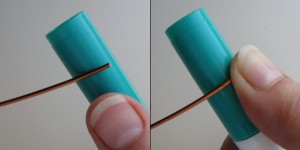

Now use the mandrel (ie: fat marker) to shape the sides of the heart. 16 g wire is a bit difficult to work with, so don’t get discouraged….! Start by holding the wire tightly on the marker, and then rolling (you are pushing – not wrapping!) the wire until you get a nice rounded shape – repeat for each side:

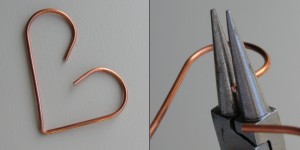

Once the sides are rounded (one side will be longer than the other), it’s time to turn the ends further inward, using the round nose pliers. It is very important to make sure that you don’t pull open the shape you just made on the mandrel! This may take a bit of practice since 16g wire is a bit difficult to work with.

It is more effective to grasp the end of the wire tightly in the round nose pliers, and then PUSH the wire around the pliers, rather than trying to pull the wire, which will warp the shape of the sides and pull them straight.

After you turn in the ends, you can shape the sides by PUSHING the ends toward each other, and gently pushing the sides out a bit, until it is the shape as shown on the right.

Using a nice slightly rounded hammer and a steel block, flatten the heart frame – the ends may open a bit, and the sides may separate a little… that’s normal, you just need to tighten up the ends and bring the sides back together, as shown above. Next, we will use thin gauge wire to wrap the sides together, so the heart doesn’t open.

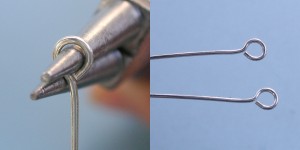

Cut about 4 inches of the thin wire (24g or 26g), and make a small hook at one end, then start to wrap the sides of the heart, as shown above. Wrap the wire through the loops on each side 3-4 times, and pull the wire taut, using your pliers as needed. Decide which side will be the front, and make sure that you pull the wire through, and cut both ends on the back.

The photo above shows the wraps neatly cut, and pressed down on the back… the only thing left is to add the bail, and hang on a chain.

I made a simple bail by wrapping a piece of 16g wire twice on the base round nose pliers, cutting and filing the ends, and hammering it a bit for texture. I then opened it and slipped it thru the loop of the higher side of the heart, so that it hangs balanced. Personally, I’m a fan of the antiqued look! If you have some wire wrapping skills, you may want to embellish the heart with additional wire wrapping, or adding some beads.

This photo shows a heart frame with spirals (the technique is similar), which is then wrapped with some faceted garnets… this is a class I’ll be teaching locally next month… just in time for Valentines Day!

You may want to check these posts for info on Hammering and on using Liver of Sulpher for Antiquing.