I doodle with wire… that’s right, I’m a doodler! When I’m sitting in front of the TV, I often have a few spools of copper wire in front me, along with my tools, and just twist and wrap and fold and coil! Seeing different designs and ideas come together is very satisfying!

Sometimes I start out with a sketch that I made, and see how it turns out. And sometimes I start with something specific in mind, to see if I can make it work. I wanted to see if I could come up with a simple circular clasp, maybe to use for some multi-stranded necklace designs, and this is how it progressed!

I had a few parameters for the clasp: I wanted clean lines, I wanted the hook side and the eye side to lay in the same direction so it would be comfortable on the neck, and it needed to be easy to use. The first “doodle” started with a figure “8” in wire, which I sorta folded over, so that the smaller loop rested on top of the bigger loop. This has a construction issue, because I would have to solder both ends to a common wire at the point where the clasp folds, leaving 2 potential weak spots.

The next doodle was similar in look, but it starts with an “O” shape that is pinched to create the two loops. This has a real advantage over the first style, in that the ends of the wire meet together, so it only has one connecting point. And since the original shape is round, it is easy to make sure the solder point doesn’t get stressed.

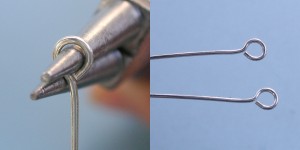

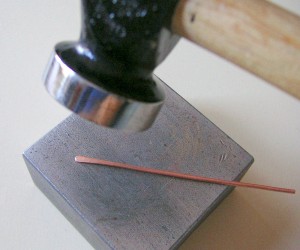

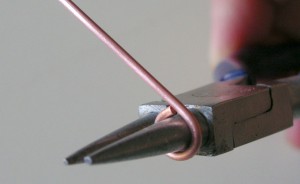

I decided to create the clasp using some twisted wire I had, and I love the end result. I started by soldering a large ring, and then shaped it like an “8” using some mandrels. Once the loops were nice and round, I carefully folded it at the place it pinched to create the hook. Next, I created the other side sizing it to the clasp.

Here is the clasp closed – you can see how the two sides are balanced, so it looks nice, both sides lay in the same direction, so it is flat against the neck, and there are no wire ends, so nothing catches onto your clothes or sticks into you.

I have tried variations of this without soldering, some work ok, but the advantage of the soldering is that it makes the clasp robust. Knowing a variety of techniques is key to being able to create your designs as you envision them…!