A Little Bling Goes A Long Way….

It can be tricky to combine the sparkle of crystal with stark metalwork, but if you keep the design sleek and simple, then the materials work together really well. Back in September, I taught a class at Hooked on Wire, and attended a presentation from the Swarovski folks… I got loads of little crystal bits (see my previous post on this HERE), and finally got around to creating a new design, which I really love!

I designed the piece using heavy gauge sterling silver (18g), which I gave a soft matte finish, and added a preset 7mm crystal rivet cup (NOTE: click on photos to enlarge):

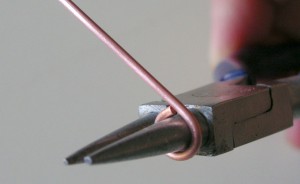

Isn’t this a great look!?! I cut a simple triangle from some scrap silver sheet I had, rounded the edges and the corners, and used a combination of files, sanding blocks, and polishing papers to get the soft finish. I then drilled a hole so I could add the crystal (the crystal comes pre-set in the rivet setting).

From the side view, you can see a bit more detail – when I drilled the hole for the crystal setting, I beveled the edge of the hole to accommodate the angle and allow the cup to seat into the silver. I curved the silver lightly to balance the formed bale – the minimalist shape provides a graceful way to hang the pendant on a chain.

The back looks a bit messier than it really is… the tube (rivet) was quite long, so I had to cut it’s length, and then cut down the tube to create tabs to fasten it to the silver. Since the rivet is brass, I was concerned that if I manipulated it too much, it would become brittle and crack. So I simply hammered the tabs down, and added a blob of E6000 to cover the tab edges so they don’t catch or scratch (E6000 is a thick adhesive).

I love how this pendant looks – right at the collarbone, showing on the skin. The crystal makes it pop, and with the matte finish on the silver, this is a piece that looks great jeans and a sweater, or all dressed up – since it’s Swarovski, the quality crystal sparkles however you wear it!

I gave this one to a friend as a thank you gift, but I’ll be making a few more, maybe even with different shapes, but the same styling. I just love when the end result looks better than what I imagined!